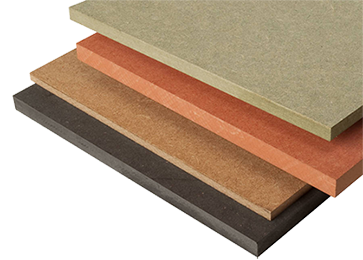

The HDF plate is a modern high-density material, high-density fibreboard. HDF boards are produced by pressing at a high temperature of chopped wood fibers of coniferous wood. HDF panels and slabs are essentially a more perfect analogue of fiberboard according to some characteristics, and the HDF density exceeds the density of the classical MDF (improved fiberboard) and it is always more than 800-1050 kg / m3. This property of HDF slabs today is highly valued in the furniture industry and construction industry. HDF has a dense and solid surface, the structure of the plates is always uniform.

The HDF plate is a modern high-density material, high-density fibreboard. HDF boards are produced by pressing at a high temperature of chopped wood fibers of coniferous wood. HDF panels and slabs are essentially a more perfect analogue of fiberboard according to some characteristics, and the HDF density exceeds the density of the classical MDF (improved fiberboard) and it is always more than 800-1050 kg / m3. This property of HDF slabs today is highly valued in the furniture industry and construction industry. HDF has a dense and solid surface, the structure of the plates is always uniform.

HDF boards and panels are widely used for:

- back walls of cabinet and upholstered furniture;

- the bottoms of boxes and boxes;

- internal (internal) doors;

- preparation of furniture facades (filling);

- manufacturing compartment doors (cabinets in the hallway);

- decorative inserts in various furniture designs;

- wall coverings (floors, ceilings);

- cladding in door panels;

- advertising samples (such as suspended ceilings, slabs, and so on).

The main advantages of HDF:

- High quality;

- Strength;

- Ecological safety;

- Ease of machining;

- Water resistance;

- Increased resistance to atmospheric conditions and chemicals.

Technical information High Density Fiberboard (HDF):

|

Sheet format |

4’x8’ (1220x2440мм), 9,18’x6,79’ (2800х2070мм), 12’x6’(3660х1830 мм) |

|

Thickness |

from 3 till 40 mm |

|

The average density (kg/m3) |

from 800 till 890 |

|

Formaldehyde content (mg/100g) |

emission class E1, E 0,5 |